TSMC is in celebratory mood as it has recently passed a gargantuan milestone. According to a blog post published by the world's largest contract chip manufacturer, it manufactured its billionth 7nm chip this July, so must be well past that number by now. TSMC started 7nm volume production in April 2018.

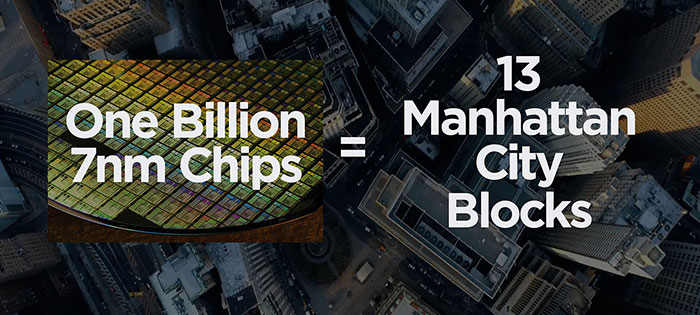

Just in case a billion was rather underwhelming in your perception, TSMC puts its feat into exa-perspective by revealing that to create those chips it fabricated over one quintillion 7nm transistors. If you are looking for a real-world scale illustration, it goes on to claim that it has output "enough silicon to cover more than 13 Manhattan city blocks," to reach this major milestone.

TSMC seems to be rather proud of its 7nm success. In a section of the blog posted headed 'practice makes perfect' it mentions how it has upped the quality and yield faster than ever before, even though 7nm marked the introduction of the long-anticipated extreme ultraviolet (EUV) lithography. Thanks to stringent quality control, supported by AI and ML technologies on the production lines, TSMC achieved automotive-grade quality for 7nm in 2019.

The chip foundry's efforts and good progress in 7nm means that its N6 process, in volume production today, is lined up for partners already. N6 is touted to deliver nearly 20% logic density improvement, making it more cost-effective, and its design rules are completely compatible with its N7 predecessor. Moreover, TSMC claims it will cement its lead by beginning 5nm volume production this year.

As a reminder, Intel recently told investors that its 7nm CPU products will be delayed a further six months - meaning products featuring the process won't be available until late 2022 or early 2023. In the meantime Intel reckons its 10nm SuperFin technology delivers processor enhancements comparable to a full node transition.