The little things matter

Chip manufacturer Global Foundries held its second annual Global Technology Conference (GTC2011) in Silicon Valley today, and among the many revelations was the announcement of a new 28nm technology aimed at mobile applications.

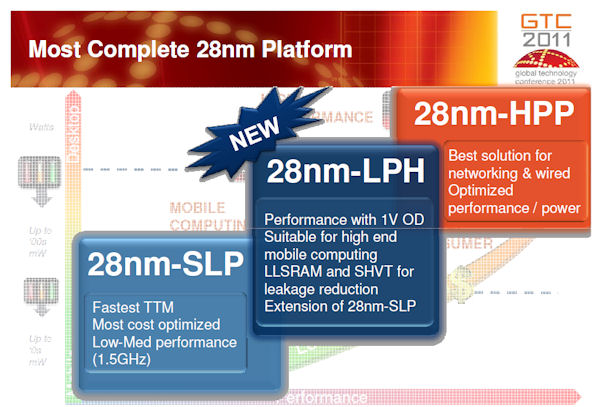

It's called 28nm LPH (low power, high performance) and, as you can see in the first slide below, GF is positioning it as the middle of three 28nm processes. 28nm is the next-generation manufacturing process that will enable the likes of Samsung, Qualcomm, etc to make SoCs that offer higher performance at lower power envelopes.

This process is aimed at high-end smartphones and tablets; offering a compromise between power and performance. GF claims it offers 60 percent active power reduction at the same frequency, or a 55 percent performance increase at the same level of leakage, when compared to 45nm low-power SoC designs.

This joint effort between GF and Samsung cements the previously-announced ‘fab synchronization' initiative, which also includes IBM and STMicro. This bloc is presenting itself as the main alternative to TSMC in the foundry game, by offering manufacturing capacity at the GF sites in Dresden and upstate New York, and Samsung fabs in Korea and Texas. They consider this geographical spread to be a competitive advantage over Taiwan-based TSMC.

"We are pleased to offer smart, innovative foundry solutions to our customers through this unique collaboration. This 28nm process will be the first semiconductor technology to truly eliminate the border between desktop computers and mobile devices," said Jay Min, VP of foundry marketing at Samsung Electronics.

"With this new collaboration, we are making one of the industry's strongest manufacturing partnerships even stronger, while giving customers another platform to drive innovation in mobile technology," said Jim Kupec, sales and marketing SVP at GF. "Customers using this new offering will gain accelerated time to volume production and assurance of supply, and they will be able to leverage significant learning from the foundry industry's first high-volume ramp of HKMG technology at 32nm in 1H 2011."

Furthermore GF also revealed some more details about the next process along - 20nm. As you can see from the slide below, it promises a 35 percent performance increase over 28nm, at twice the density, and is scheduled to start production in 2013.

GF considers technology and capacity to be key competitive factors in trying to take business from TSMC, and collaborations such as this help it in both respects. It is, however, debatable whether collaborating so closely with Samsung will help GF land possibly the biggest foundry catch of all - Apple.