Microsoft has partnered with high-end domestic appliance firm Miele to leverage its IoT technologies to create smarter home appliances. Coincidentally Fujitsu has just announced its collaboration with Microsoft to improve factory manufacturing processes through IoT innovation. Both announcements emanate from the Hannover Messe event which is on this week. The deployment of the Internet of Things (IoT) and Internet of Services (IoS) to create smart factories has been dubbed Industry 4.0.

Many people will know Miele makes a wide range of white goods and other household appliances but its Microsoft collaboration centres around oven cooking. Miele and Microsoft have developed a website where users select recipes. Once selected food preparation stages are downloaded to the user's smartphone or tablet and the matching program is loaded onto the oven through Microsoft Azure. The oven varies temperature, cooking time, humidity (by adding steam) and other factors to match the recipe to help cook your meal to perfection.

Perfect putenbraten is easy thanks to Microsoft and Miele

Caglayan Arkan, general manager, Worldwide Manufacturing and Resources at Microsoft, said that "This is just one example of how the Internet of Things and cloud technology are moving from enterprise experiences to personal experiences". The IoT implementation could go beyond cooking to include remote diagnostics and predictive maintenance of the oven.

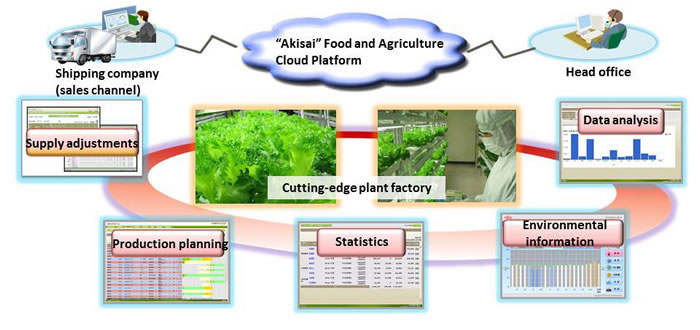

Fujitsu's collaboration with Microsoft IoT and Azure comes from a different angle and aims to improve factory processes rather than direct customer experiences. Explaining the initiative Fujitsu says "Having recognized a solution was needed to optimize processing by both machines and humans, Fujitsu brought together its Eco-Management Dashboard, the IoT/M2M platform, Microsoft cloud services and Windows tablets in a way that could enable managers, engineers and scientists to improve product quality, streamline systems and enhance functionality while reducing costs".

The facility where Fujitsu is testing its IoT partnership with Microsoft is a mothballed semiconductor factory - unused due to unneeded capacity. Instead of making silicon chips the factory is now producing lettuce – based on the same quality management techniques employed to optimise its semiconductor manufacturing. It's a good test-bed for the IoT and M2m (machine to machine) and Microsoft mobile technology. The facility produces low potassium lettuce for kidney dialysis patients, and is transforming the perception of agriculture.