Stacker case production line

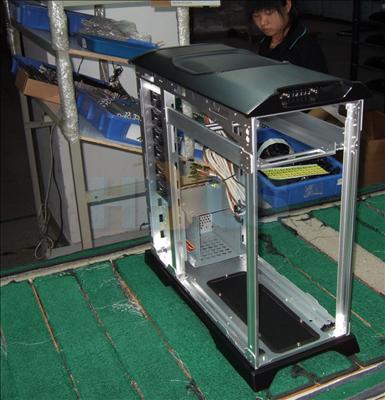

So, how does Cooler Master bring all the parts together and assemble them into a complete PC case?

You might be as surprised as we were to learn that most of its high-end cases, including the hugely popular Stacker, are hand-built on a production line with fewer than 20 people.

This is even more surprising when you consider that most of the company's high-end cases contain more than 130 rivets!

The following images illustrate the various stages of the build process and some of the parts used.

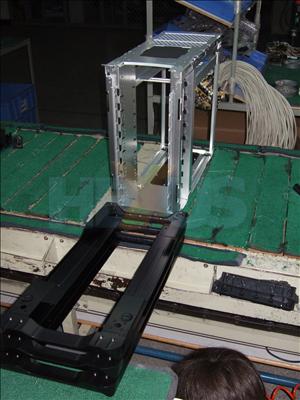

The first stage involves building up the basic skeletal structure and drive cage.

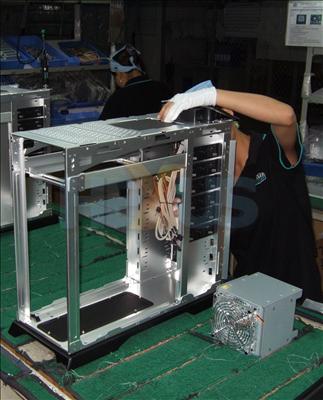

In the second stage, the top and bottom panels are attached to the structure built in stage-one.

The case under-tray and drive-bay slides are fitted next.

Then the front-panel I/O ports are installed into the plastic top-panel trim but not yet onto the case.

The front-panel I/O port top-panel trim and top-panel are installed along with a 4-in-3 HDD device module.

Case accessories are picked and installed in boxes into the drive cages of the case.

The motherboard tray is assembled ready for the next stage.

The motherboard tray is installed into the case and the visible plastic surfaces, such as the front and top panels, are wiped-over.

Finally, side-panels are installed onto the chassis.