Researchers from the University of Michigan have developed a new 3D printing technique that is 100x faster than conventional 3D printing. As the UM news centre explains, the new 3D printing method lifts complex shapes from a vat of resin, and as well as being faster, the solidified object is significantly tougher, more durable and wear resistant.

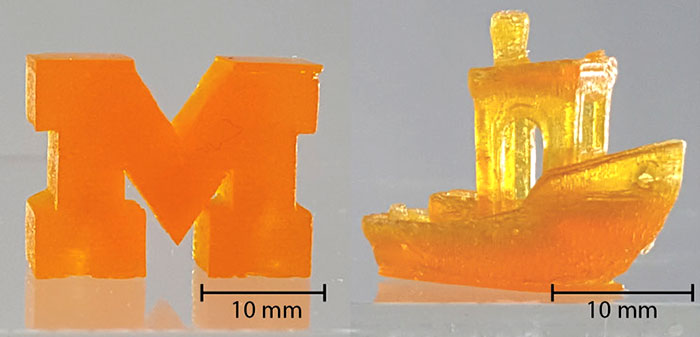

In the video above you can see the new UM 3D printing method in action. The letter M is formed in the demo in 14s with the video speed running at 6x, meaning that the object was 3D printed using resin and mixed lighting in under one and a half minutes. (Object dimensions are indicated in the image below)

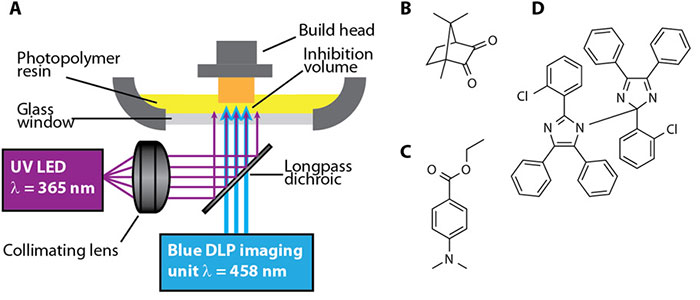

Explaining the new 3D printing method isn't that complicated. In essence two lights control where the resin hardens and where hardening is inhibited as the shape rises from the resin pool. Thus "they can make a 3D bas-relief in a single shot rather than in a series of 1D lines or 2D cross-section," one of the key aspects of this technique which imbues strength to the finished products.

A key advancement of the UM technique is in the resin chemistry to enable the above behaviour. This important change is described clearly below:

In conventional systems, there is only one reaction. A photoactivator hardens the resin wherever light shines. In the Michigan system, there is also a photoinhibitor, which responds to a different wavelength of light. Rather than merely controlling solidification in a 2D plane, as current vat-printing techniques do, the Michigan team can pattern the two kinds of light to harden the resin at essentially any 3D place near the illumination window.

The University of Michigan has already patented this tech - protecting it with three patents. Furthermore, Timothy Scott, an associate professor of chemical engineering at UM, who co-led the development of the new 3D printing approach with Mark Burns, is preparing to launch a startup to commercialise the new 3D printing approach.

You can read more about this 3D printing development in a paper titled 'Rapid, continuous additive manufacturing by volumetric polymerization inhibition patterning,' published in Science Advances.