Floor 5 – DIP – part 2 (VGA)

It's not just about motherboards, as we saw from the production lists. The factory can churn out 600,000 graphics cards per year, too.Here's one of the equipment stores in the form of encapsulated ferrite chokes awaiting assembly on VGA cards.

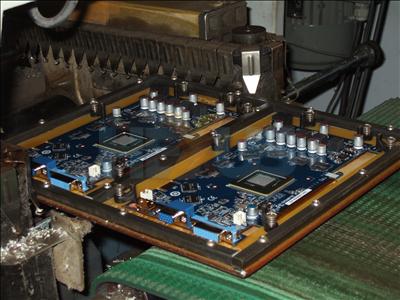

Start of the VGA production line. As on the motherboard production line, the boards are mounted onto metal frames used to support them during the wave-soldering process.

Different stages of the manual insertion process. And you thought you had a boring, repetitive job!

Graphics cards about to enter the wave-solder machine.

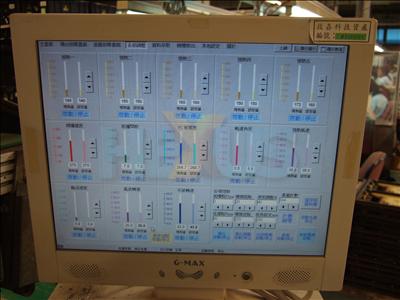

Note that the wave-solder machine used for the graphics cards is more modern design than that used for the motherboards, and has PC monitoring and control.

Boards after they’ve just left the wave-solder machine.

As per the motherboards, here are graphics cards going through touch-up and solder-side inspection.

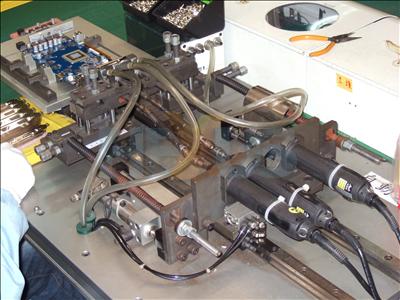

Assembly of the back plates onto the graphics cards using a special tool.

Heatsinks ready for assembly on the graphics cards.

Assembly of the heatsinks on the graphic cards. We bet she can do it 2x faster than any of our readers.

The finished graphics-card after touch-up, solder-side inspection, and heatsink assembly.