The modern world is full of metallic, shiny objects, but future worlds, often portrayed in popular computer games, are often more so. However, up until the current time there has been no way that computer graphics software could realistically portray the 'glints' in shiny metallic surfaces except for in stills. Now thanks to researchers, led by Professor Ravi Ramamoorthi at the University of California San Diego, your metallic graphics in motion "could look a lot more realistic," reports the UC San Diego Jacobs School of Engineering blog. As presented at the SIGGRAPH 2016 in Anaheim, California, Ramamoorthi's new glints rendering method "requires minimal computational resources and can be used in animations".

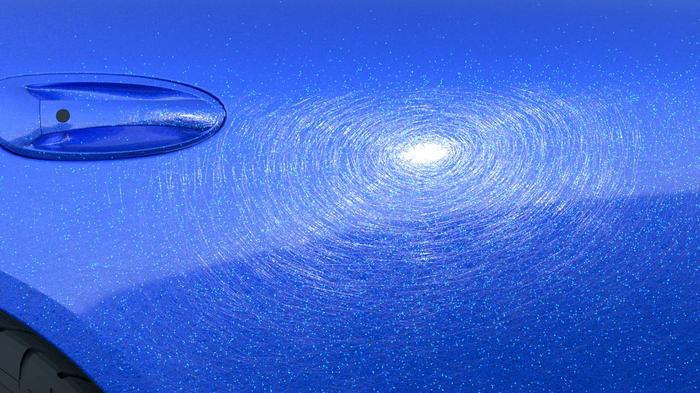

Don't clean your car with a brillo pad

Summing up the problem in hand Ramamoorthi said "There is currently no algorithm that can efficiently render the rough appearance of real specular surfaces." He added that this situation "is highly unusual in modern computer graphics, where almost any other scene can be rendered given enough computing power."

Current state-of-the-art methods render metallic and similar surfaces incorrectly making such objects "noisy, grainy or glittery" but the new rendering method doesn't assume surfaces are smooth at the pixel level. The new method breaks down each pixel of an uneven, intricate surface into pieces covered by thousands of light-reflecting points smaller than a pixel, called microfacets. Its glint reflection properties are derived from the microfacet angle. Another way of describing the new method is that it "treats a specular surface as a four-dimensional position-normal distribution, and fits this distribution using a mixture of 4D Gaussian flakes". The key to the 100x algorithm speed improvement is said to be in approximating the microfacet angle, saving valuable time and compute power.

Is this scene a little too oily looking?

These glints can be applied to surfaces beyond the aforementioned metals, to shiny fabrics, leather and wood finishes for example (see directly above). A link to the full PDF paper is available here. In addition to Prof Ramamoorthi, study co-authors include; Ling-Qi Yan, from the University of California, Berkeley, Milos Hasan from Autodesk, and Steve Marschner from Cornell University.