British company ARM® specialises in designing the CPU architecture that powers the vast majority of smartphones and tablets available today. Not only that, ARM also builds the blueprints for processors that reside in such eclectic products as washing machines and smart lighting. Any 'smart' device is likely to have ARM technology inside.

Energy efficiency are two key buzzwords that surround the ARM ecosystem, with partners building ever-more-efficient devices that promise increased battery life without compromising on performance. Looking down the track, to the next five years or so, it is prudent to understand just how much more efficiency can ARM wring out of its mobile-optimised architectures.

Simpler is better for energy efficiency

The broad ARM processor portfolio is based upon the lean, energy efficient ARM architecture. With each generation of processor, energy efficiency has remained a design cornerstone, while performance has increased to keep pace with the demands of tomorrow’s digital lifestyle.

For example, the mainstream ARM Cortex®-A7 CPU provides up to 20 per cent more performance compared to the Cortex-A5 CPU at similar energy efficiency, while the Cortex-A15 processor delivers twice the performance of smartphones based on the Cortex-A9 processor, with a small increase in power consumption.

Although the energy efficient Cortex-A7 and the high performance Cortex-A15 can serve completely different markets in standalone implementations, it may be surprising to learn that the architecture and feature set of the two processors is identical. Getting the most out of the two by exploiting their strengths, ARM has a CPU-pairing technology known as big.LITTLE processing, where sets of high-performance and energy-efficient cores are used when it makes sense to do so - the big cluster for heavy processing and LITTLE for light background tasks.

Looking towards the future, it is highly unlikely that high-end CPUs will be able to match the energy efficiency of low-end models. On top of the more-complex architecture, high-end CPUs tend to use silicon that is primed for speed, whereas low-end CPUs are baked on silicon purposely designed for lower leakage and more energy efficiency. This process specialisation is key in ensuring lower-end CPUs remain more energy efficient.

Energy efficiency at the platform level

ARM understands that the pursuit for low-power processing has to be considered from a platform or system-on-chip (SoC) point of view. The CPU and, to a lesser extent, GPU steal the limelight, but overall platform-level savings are just as important. In fact, when comparing modern-day processors it is more important to look at total platform or SoC power than CPU or GPU alone.

ARM has worked very hard with its wide range of partners to ensure that all the pieces that constitute the SoC jigsaw interoperate with one another with the least amount of power. Measures include extensive clock-gating, granular cache management, using advanced framebuffer compression to limit the amount of bandwidth coursing through an SoC, and using the very latest manufacturing technologies on cutting-edge processors such as the Cortex-A57. ARM understands that it's also very important to reduce idle power as most devices rarely run at full gallop at most times.

Marginal gains in power efficiency add up when considered from a platform point of view. Appreciating that ARM operates in a mobile world, increasing power efficiency enables device manufacturers to either extend the battery life of existing products or, should they so wish, increase the performance without sacrificing run time.

Increasing efficiency via manufacturing improvements

Power consumption can be curbed by combining a slew of techniques that are discussed above. Reducing power substantially further requires fundamental improvements in the manufacturing process. Manufacturing partner TSMC has already announced that the next generation of high-end ARM CPU designs is to be built on a 16nm FinFET process. FinFET transistors use 3D structures that wrap around the channel and thus ensure that very little current is leaked when switched off, and this is hugely important as it enables FinFETs to run up to 40 per cent faster at a lower power threshold or to reduce current leakage by up to 90 per cent when compared to planar transistors.

Advancements in manufacturing, led by FinFET, are likely to push the performance potential of next-generation ARM architectures to way beyond what's possible from today's devices. And when technologies such as FinFET and smaller manufacturing processes migrate to the mainstream at a later date, mid-range devices will rival the processing power of today's premier handsets and tablets while sipping on a fraction of their power.

How low can the ARM architecture go?

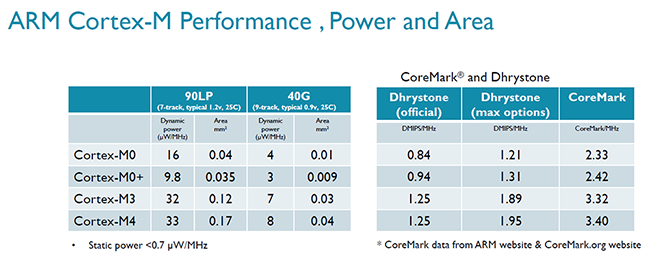

The ARM Cortex-A series grabs the headlines because it's featured in some of today's most recognisable handsets and tablets. These application processors are at the high-end of ARM's portfolio, with Cortex-R and Cortex-M series processors featuring heavily in embedded devices and microcontrollers. To give you an idea of how energy-efficient today's Cortex-M series of processors can be, here are some mind-boggling numbers.

The Cortex-M0, for example, readily found in everything from hard drives to washing machines, uses just four microwatts for every MHz - that's four-millionths of a watt! Fabricated on a 40nm process, the CPU core measures just 0.01mm². The Cortex-M0+ is even more energy efficient, and Freescale has used it to build a complete processor package that is smaller than the dimple on a golf ball.

Power efficiency is one of the ARM ecosystem's key strengths. The simple, uncomplicated architecture naturally lends itself to processors that are ideal for the mobile world. Imminent improvements in manufacturing process and ARM's continued drive towards leaner architectures means the next three to five years should bear witness to significantly more processing power than available today. We may well look back in 2019 and view today’s top-of-the-range smartphones as curiously anaemic devices.