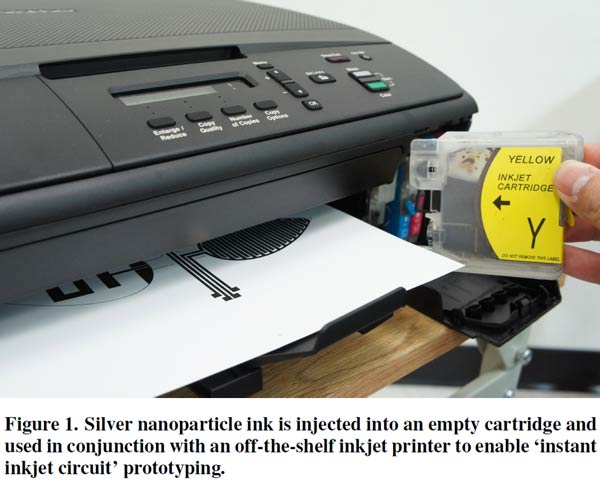

A new technique developed by researchers from Georgia Tech, the University of Tokyo and Microsoft Research enables quick and cheap printing of electrical circuits. All an interested person needs is a common-or-garden inkjet printer and a few off-the-shelf materials which shouldn’t add up to costing more than $300, Printed Electronics World reports.

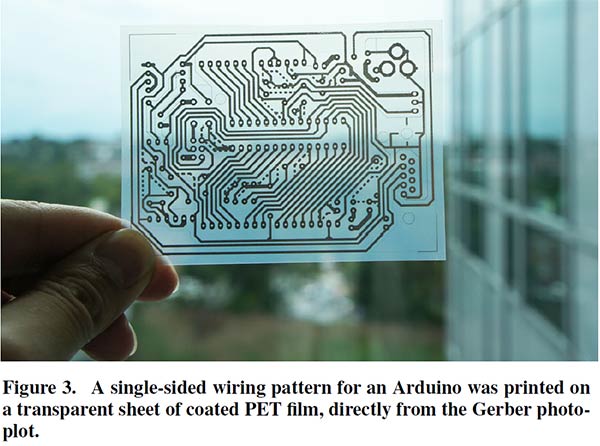

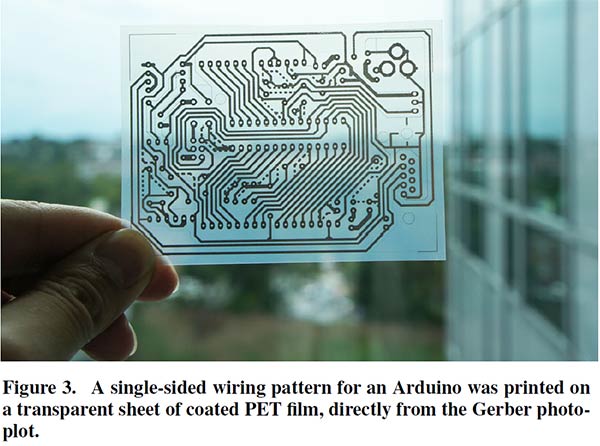

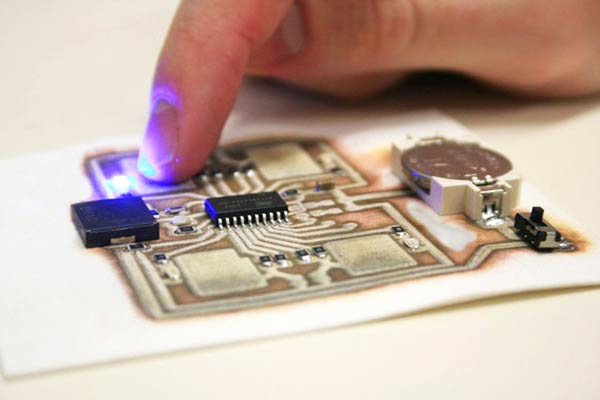

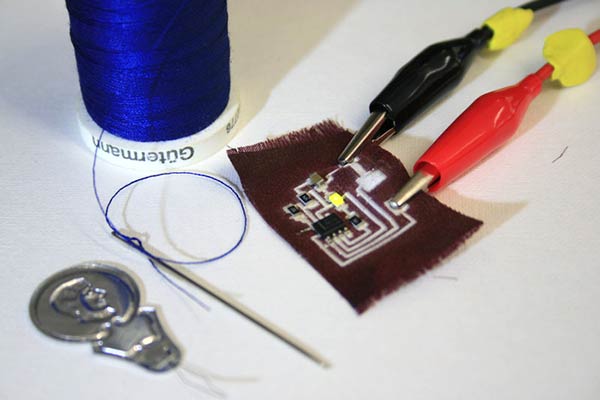

The team based at Georgia Tech used the commonly available printing equipment and materials to print custom designed circuitry onto various materials, both rigid and flexible. Using conductive silver nanoparticle ink circuits could be printed upon materials such as PET film, glossy photo paper and resin coated paper. It is thought that this printing innovation could speed up electronics design prototyping and be a boon for enthusiasts and hackers alike.

“We believe there is an opportunity to introduce a new approach to the rapid prototyping of fully custom-printed circuits,” said Gregory Abowd, Regents' Professor in the School of Interactive Computing at Georgia Tech and an investigator in the study. “Unlike existing methods for printing conductive patterns, conductivity in our technique emerges within a few seconds and without the need for special equipment.”

Previously the silver nanoparticles used to require thermal bonding, which made printing on the aforementioned examples of papers and film plastics impractical. Using a new chemical bonding technique such pitfalls are avoided. However there are some surfaces which aren’t suitable; for instance canvas and magnet sheets should be avoided, we are told.

Once you have your circuit board printed you won’t want to solder in your other components as that could set fire to your paper or plastic. The researchers suggest attaching components using conductive double-sided tape or silver epoxy adhesive. Printed Electronics World says that electronic tinkerers can quickly prototype electronic devices such as calculators, thermostats and others in mere hours.

Steve Hodges, from Microsoft Research, said “Using this technology in the classroom, it would be possible to introduce students to basic electronics principles very cheaply, and they could use a range of electronic components to augment the experience”.

Cartesian EX1 3D circuit board printer

In related news a Kickstarter project for a 3D circuit board printer called the EX¹, by Cartesian Co., has achieved double its funding target of $30,000 in just two days. Here’s what the developers say about their machine “The EX¹ printer is not designed to create any 3D object like normal 3D printers. It’s been crafted and designed for one key purpose, to allow you to 3D print circuit boards, layering silver nanoparticles onto paper or any suitable surface to rapidly create a circuit board.”

The EX¹ can print upon plastic (many types), glass, wood, ceramic, silicone, fabric and paper. It is great for making wearable tech targeted circuitry. Like the silver nanoparticle printing technique outlined above, by the researchers from Georgia Tech, the EX¹ uses chemical bonding of the silver to the printing surface. Two cartridges hold two different substances which react together to leave a silver image firmly upon the material surface. The Cartesian Co. hopes that the printer “will allow people to design and make radically new things”.

At the time of writing the cheapest backing option to receive a printer kit from the EX1 Kickstarter project is $1,499 - and you’ll have to wait until September 2014.