There is still headroom for Moore's law to apply to chip design/manufacture for the next few years according to Intel scientists. At the International Solid-State Circuits Conference (ISSCC) in San Francisco this week Intel will discuss the challenges it faces in manufacturing ever faster and more efficient chips, expected to be made with 10nm process technology in the near future.

Intel senior fellow Mark Bohr engaged in a conference call with reporters discussing the upcoming Intel ISSCC presentations. Bohr said that current processor making technology can be used to make ever-finer-scale chips from the 14nm processors we have today, down to smaller processes in the future. However looking further down the line new "expensive, esoteric manufacturing methods like ultraviolet lasers," might be required to follow Moore's Law, reports PC World.

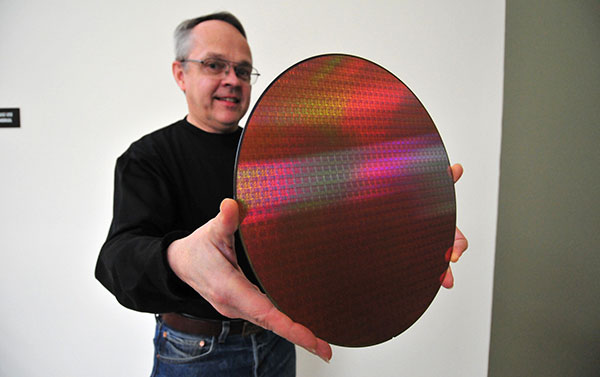

Mark Bohr

This year marks the 50th anniversary of Moore's Law, which is a computer industry observation that says "the number of transistors in a dense integrated circuit doubles approximately every two years". Intel co-founder Gordon E. Moore described the trend for the first time in 1965. The process shrinks, described in nm scales above, are vital to maintain Moore's Law without any other radical change in computer chip making technology.

Intel's Bohr took the time during his conference call to explain the manufacturing delay of the 14nm Broadwell chips. He said that the firm underestimated the time needed to complete the tasks required to ready the chips. Then it took longer to "fix the yields," but he noted that Intel is now enjoying high yields. Furthermore you might be happy to hear that the 10nm process pilot is on track, and going about 50 per cent faster than 14nm development did.

Faster processing is required for this kind of thing, thinks Intel