University of Texas engineers have successfully made the first silicene transistors. Excitingly these electronics components performed in line with the extraordinary switching speeds that had been promised in theory. The breakthrough moves the material closer to its potential of creating a future generation of dramatically faster computers, and marks the first time that anyone has been able to fabricate a field-effect transistor out of silicene.

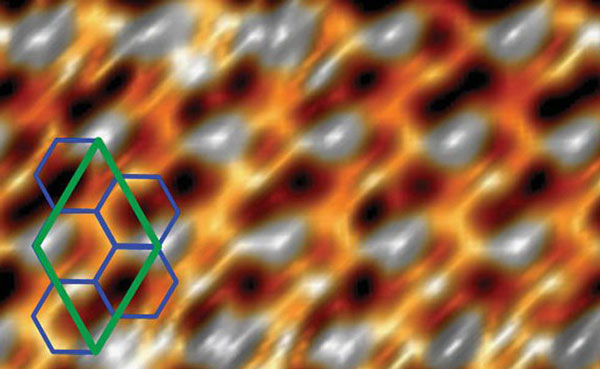

Silicene material is a single-atom thick layer of silicon with its structure resulting in fantastic electrical properties that could soon be adopted by the semiconductor industry. While lacking some of the impressive qualities of graphene, which is also a single-atom thick material (but made of carbon), silicene demonstrates similar electrical properties, including allowing electrons to travel through the material with minimal barriers or resistance.

Researchers are interested in the potential of silicene due to its relationship to silicon, which is the staple of modern electronics. Once silicene production is more reliable, it should be easier and less expensive for the electronics industry to adopt compared to a switch to graphene.

The structure of silicene means that the material is very difficult to produce and work with, but its development could make future computer chips dramatically faster, smaller and more efficient. Computer engineer Deji Akinwande has figured out a milestone method to manipulate this stubborn and unstable material well enough to make the first working silicene transistors.

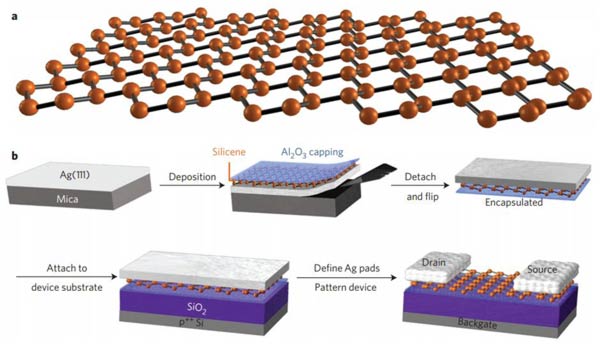

"Once silicene is made, its instability means it must be protected, and that makes it difficult to work with. Akinwande found a way around this problem by growing silicene on a thin film of silver capped with aluminum oxide. The whole thing is then peeled off, and then placed on a silicon dioxide wafer with the silver side up. Finally, the silver is patterned to make the electrical contacts for a transistor. Once the device is finished, it is stable under vacuum conditions," MIT Technology Review explains.

Although the above outlined technique may not have applications in commercial practice, the research does confirm the material's impressive electrical properties. Akinwande's research should become milestone for the industry, spurring him and others in the field to forge ahead in looking to find new methods for the large-scale manufacturing of silicone components.