When we first reviewed Intel's Core i7-3770K Ivy Bridge processor back in April, we noted that when overclocking, even with a dual-fan Corsair A70 cooling solution, the CPU reached temperatures of 75 degrees, limiting the maximum reachable clock, leaving Sandy Bridge with the most overclocking legroom.

It has since been revealed, following intense forum discussion, with a report on the matter first from overclockers and then confirmed by Japanese tech portal, PC Watch, that Intel has moved away from using the fluxless solder found in Sandy Bridge and is instead applying run-of-the-mill thermal interface material paste, to join the chip's integrated heat spreader to the CPU die.

Though exact figures remain a secret, fluxless solder generally has a much improved thermal conductivity, typically in the range of 80W/mK, whilst a standard TIM paste has only 5W/mK, making the new solution potentially 16 times less efficient.

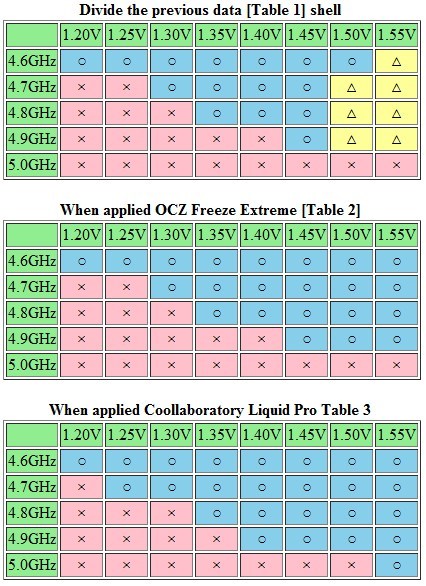

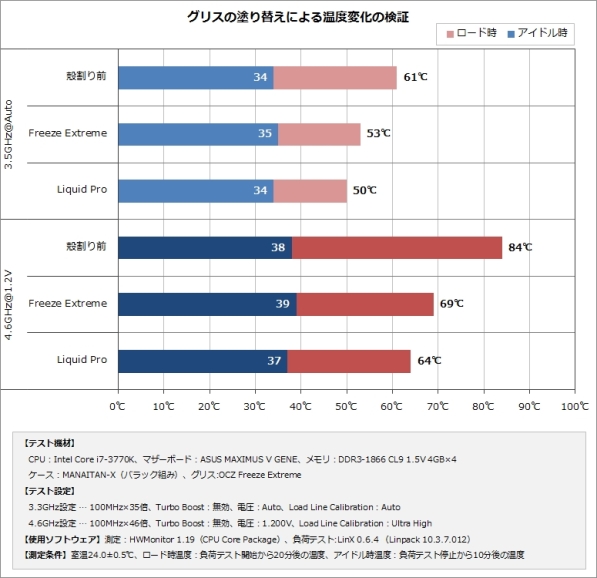

With increasing die power densities, Ivy bridge should be even more demanding on thermal dissipation per metre, yet, thanks to testing from a PC Watch investigator, where the Ivy Bridge TIM was replaced with aftermarket alternatives, it was proven that the stock-TIM was the primary culprit in increased Ivy Bridge temperatures, with results showing stock temperature drops of up to 18 per cent and, temperature drops at 4GHz @ 1.2V of up to 23 per cent, using Coolaboratory TIM as an alternative paste.

Ultimately, the modifications at PC Watch enabled new overclocking headroom. Given the amount of money a typical overclocker spends on a motherboard with a good quality power supply, higher performance RAM and cooling solutions, it feels quite the let down to discover that Ivy Bridge's bottleneck is one inherent in the chip from day one.