Quality-assurance testing equipment

Quality assurance is vital to product reliability - and Cooler Master's Huizhou facility has more than $1 million dollars of equipment to test and measure different criteria.

The company aims to maintain quality at set levels to ensure that products work as intended when they finally arrive with users. Part of that process involves making sure that the packaging allows the contents to stand up to the harsh treatment it can receive when being handled all down the distribution channel.

Here's an overview of some of the most important pieces of test kit.

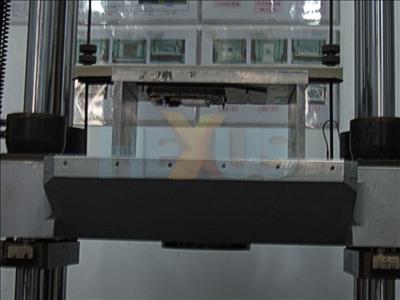

Shock tester

This device is used to simulate a controlled shock. An adjustable hydraulic ram on the platform allows the operator to simulate the desired level and duration of shock - measured in Gs.

In this picture you can see a PCB mounted upside-down being tested to check that the cooler won't come off.

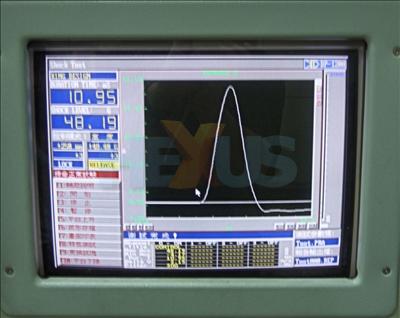

The computer readout below shows that the device was tested at 48.19G and that the duration of the shock was 10.95ms.

Drop tester

A considerable number of product failures that you'll have experienced will have resulted from the product being dropped before it arrives with you - by a courier, a warehouse-man, a fork-lift driver or any of a whole bunch of people who will have had to handle the goods.

Clearly, the design and construction of packaging are critical to how well product is protected and the machine shown below is designed to check the effectiveness of packaging.

The machine can be set up so that boxes are dropped from different heights and onto any of their sides.

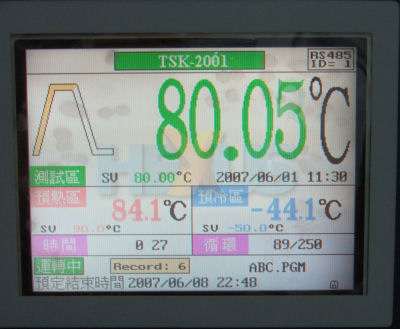

Thermal-shock tester

Thermal shock can be another product-killer or, at very least, can impact severely on performance. The kit shown below is used to gauge the result of thermal shocks - such as a PC in a very cold room being turned on - and is usually operated across a temperature range of -55 C to 150 C.

Below, the product being tested is currently baking at a toasty 80 degrees Celsius.

Salt-sprayer tester

Because many products are shipped by sea to keep down costs, it's important to know if they're likely to corrode on the journey as a result of salty sea spray that can splash the giant containers they're packed within. This device sprays a salt-water mist over the items to be tested in order to know the oxidisation time.